Struggling with choosing the right submersible pump or facing issues like rust or leaks? These problems can lead to significant delays and increased repair costs. Understanding how submersible pumps function and how to maintain them ensures optimal performance and longevity.

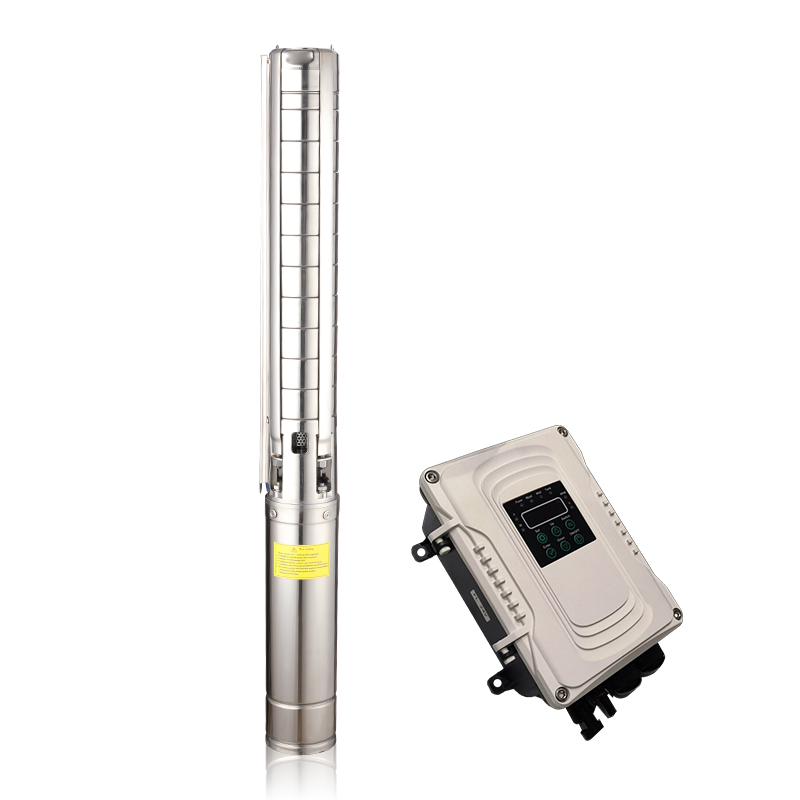

Submersible pumps are designed to operate underwater, efficiently moving water from one place to another. Whether for a water well, drainage, or sump applications, they work by converting electrical energy into mechanical energy to pump water.

Understanding the mechanics of submersible pumps, including how to choose the right size, prevent rust, and address common issues, is essential for maintaining their long-term functionality. Let’s dive deeper into how submersible pumps work and what you need to know to keep them running efficiently.

How Do We Know What Size Submersible Pump We Need?

Choosing the right size submersible pump for your application is crucial for efficiency and long-term reliability. The size of a submersible pump depends on several factors:

- Flow Rate: The flow rate, measured in gallons per minute (GPM), indicates how much water the pump can move in a given time. Determine the required flow rate based on the volume of water you need to pump and the size of the area or well.

- Head Height: This refers to the vertical distance the pump needs to lift water. The higher the head, the larger the pump should be. Make sure to account for the total head height (vertical distance plus any friction loss in the pipes).

- Pump Type: Whether you need a submersible well pump or a sump pump submersible will depend on the specific application. Different pumps are designed to handle varying water volumes and depths.

Selecting the correct size ensures efficiency and prevents overworking the pump, leading to premature wear or inadequate performance.

What Causes a Water Well Pump to Rust?

Rust in submersible well pumps can cause significant damage and reduce their efficiency. Several factors contribute to the rusting of a pump:

- Water Composition: High levels of minerals like iron or sulfur in the water can accelerate the corrosion process. If the water has high acidity or high iron content, it can cause the pump parts to rust more quickly.

- Lack of Maintenance: Regular maintenance is crucial. If the pump is not cleaned and inspected regularly, rust and corrosion can set in, especially if the pump is submerged for long periods without service.

- Age of the Pump: Older pumps made of materials that aren’t corrosion-resistant are more prone to rust. Over time, pumps naturally wear down, and the protective coatings may fail, allowing rust to develop.

- Inadequate Materials: If the pump is made from low-quality materials that aren’t resistant to corrosion, rust will form more easily.

To prevent rust, choose a submersible water pump for wells made from corrosion-resistant materials and perform regular maintenance to ensure the pump’s longevity.

What Is the Right Way to Repair Your Leaking Sump Pumps?

If your sump pump submersible starts leaking, it can lead to significant flooding, causing damage to your basement or other areas. Repairing a leaking pump correctly involves the following steps:

- Turn Off Power: Always disconnect the pump from the power source before attempting any repairs to avoid electrical hazards.

- Check for Damage: Inspect the pump for visible cracks or signs of wear, especially around the seals. Leaking usually occurs when the pump’s casing or the seals are damaged.

- Replace the Seals: If the seals are worn or cracked, replace them. High-quality replacement parts designed for your specific model will prevent further leakage and improve the pump’s efficiency.

- Test the Pump: After replacing the seals or other damaged parts, reassemble the pump and test it by running water through it to ensure it’s functioning properly and not leaking.

Performing these repairs promptly can extend the lifespan of your pump and prevent costly damage from flooding.

What Usually Causes a Sump Pump to Break?

Sump pumps are essential for removing water from basements and preventing flooding. However, several issues can cause a sump pump submersible to break:

- Power Failure: A common cause of pump failure is a power outage. Without electricity, the pump cannot function, leading to water buildup and potential flooding.

- Clogged Discharge Lines: Debris or sediment in the discharge lines can cause blockages, preventing water from being pumped out. Over time, these blockages can damage the pump’s motor.

- Worn-Out Parts: As with any machinery, the parts of the sump pump wear out over time. Check for signs of wear on the impeller, motor, and seals.

- Improper Installation: If the pump is not correctly installed or positioned, it may not work efficiently. Ensure the pump is set up at the correct depth and aligned properly.

By regularly maintaining your sump pump and ensuring it’s properly installed, you can prevent many of the issues that lead to failure.

Summary

Understanding how submersible pumps function and properly maintaining them is essential to ensure they operate efficiently and last longer. Regular maintenance prevents issues like rust and leaks and keeps your pump in top working condition.